Ring light PCB Board Purchase Guide: Double or Single side, Seming Lighting Helps You Choose Wisely!

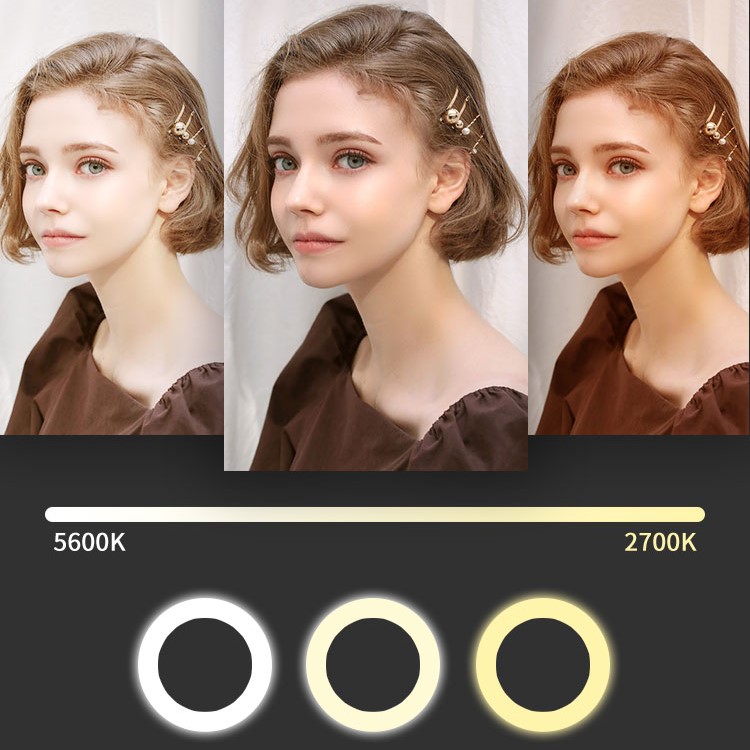

In the pursuit of perfect light and shadow

effects in the era, the ring light with its uniform and soft lighting

characteristics, has become an indispensable lighting tool in photography, live

broadcasting, beauty and other fields. However, when choosing a ring light,

have you ever been troubled by a seemingly small detail: the PCB board of the

ring light, whether to choose a double-sided or single-sided?

PCB (Printed Circuit Board, printed circuit

board), as the core component of the ring light, carries the heavy task of

electronic components and circuit connection, which directly affects the

performance, stability and service life of the ring light. Choosing the right

PCB board type is like laying a solid foundation for your lighting equipment to

perform at its best. Today, we will delve into the double-sided and

single-sided types of circular lamp PCB boards to help you better understand

their differences and make an informed choice based on your actual needs. At

the same time, Seming Lighting, as a professional supplier in the lighting

industry, will provide you with professional purchase advice, so that you are

no longer confused when choosing a ring lamp PCB board.

Recognize the two main types of ring light PCBS

First of all, we need to understand the two

main types of circular lamp PCB board: single-sided PCB and double-sided PCB.

They differ significantly in structure, performance and application.

Single-sided PCB: a cost-effective option

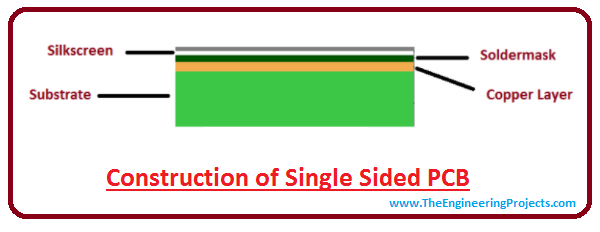

Single-Sided PCB (single-sided PCB), as the

name suggests, refers to a PCB board with a conductive layer and electronic

components on one side of the PCB board. This type of PCB board has simple

structure, low manufacturing cost, and is suitable for some simple application

scenarios with low performance requirements. The characteristics of

single-sided PCB mainly include:

1. Low cost: simple structure, relatively

low manufacturing cost, suitable for cost-sensitive application scenarios.

2. Simple structure: the conductive layer

and electronic components are on the same side, the wiring space is limited,

and it is difficult to achieve complex functions.

3. Limited heat dissipation performance:

Because there is only a single conductive layer, the heat dissipation capacity

is limited, which can easily lead to overheating of components.

Double-sided PCB: Guarantee of performance

and reliability

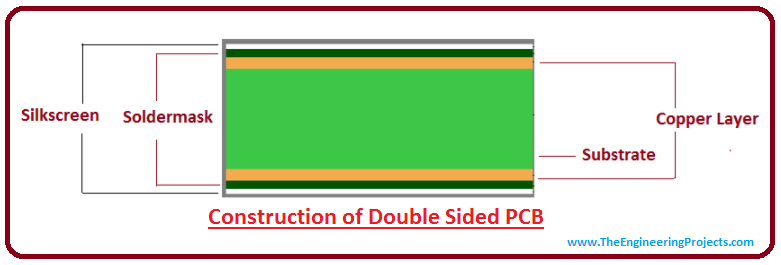

Double-Sided PCB (double-sided PCB) is a

circuit board with conductive layers and electronic components on both sides of

the PCB. Double-sided PCBS connect circuits on both sides through holes,

enabling more flexible wiring and higher integration. The characteristics of

double-sided PCB mainly include:

Both sides can be wired, higher design

freedom, can achieve more complex functions.

Better heat dissipation: By connecting both

sides of the hole, the heat dissipation path is shorter, the heat dissipation

efficiency is higher, and the component temperature can be effectively reduced.

Higher reliability: the structure is more stable, the anti-interference ability

is stronger, and it is not easy to be affected by the environment.

High cost: The structure is more complex,

and the manufacturing cost is relatively high.

Quality difference between double-sided and single-sided

PCB (simple comparison)

The difference in quality between

single-sided PCB and double-sided PCB is mainly reflected in the following

aspects:

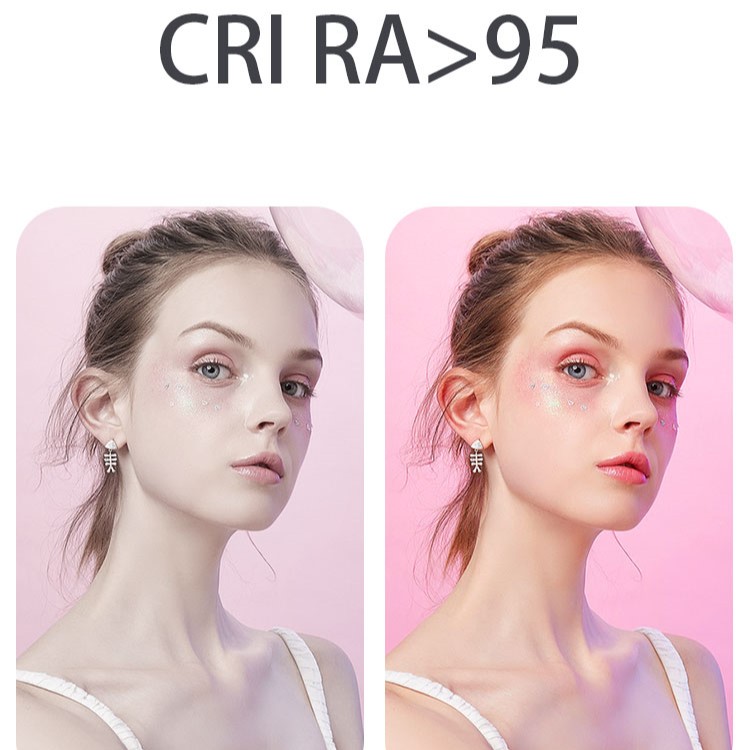

Electrical conductivity:

Both sides of the double-sided PCB have

conductive layers, which can provide better electrical conductivity and can

carry greater current. Single-sided PCB only single-layer conduction,

conductivity is relatively weak.

Application scenario: If the ring lamp needs higher brightness or more LED lamp beads, it

is recommended to choose double-sided PCB.

Heat dissipation:

The double-sided PCB has a shorter thermal

conductivity path and can dissipate heat more quickly. Single-sided PCB heat

dissipation efficiency is relatively low.

Application scenario: If the ring lamp is used for a long time or requires high

brightness lighting and large heat output, it is recommended to choose a

double-sided PCB with better heat dissipation performance.

Reliability:

Double-sided PCB structure is more stable,

not easy to deformation, stronger anti-interference ability, higher

reliability, longer service life. Single-sided PCBS are relatively more

susceptible to environmental factors.

Application scenario: If you need to use ring lights in harsh environments, or need to

work stably for a long time, it is recommended to choose double-sided PCB to

ensure higher reliability.

Cost:

Explanation: Single-sided PCB has simple structure and low manufacturing cost.

Double-sided PCB structure is more complex, the cost is relatively high.

Application scenario: If the budget is limited and the performance requirements are not

high, you can choose single-sided PCB. If there are high requirements for

performance and reliability, it is recommended to choose double-sided PCB,

which is more cost-effective in long-term use.

How to choose ring light PCB in different application

scenarios

So, in practical applications, how to

choose the right type of PCB according to the needs? Seming Lighting will

provide you with the following suggestions:

Personal fill light:

Features: Low

power, short use time, simple function, more sensitive to cost.

Recommendation: Single-sided PCB is usually

enough to meet the needs, but if the budget allows, choose two-sided PCB can

get better heat dissipation effect and service life.

Live beauty light:

Features: Medium

power, long time use, color restoration and stability have certain

requirements.

Suggestion: It

is recommended to use double-sided PCB to ensure stable light output, and

obtain better heat dissipation performance and extend service life.

Professional photography Lights:

Features: High power, long time use, high requirements for brightness, heat dissipation

and reliability.

Recommendation: Double-sided PCB must be used, and a better heat dissipation design

must be considered to ensure a stable light output and extend the service life

of the equipment.

Special Application:

Features: Used in high temperature, high humidity and other special environment.

Recommendation: A more reliable double-sided PCB must be used to ensure that it

works properly in harsh environments.

How can Seming Lighting help you choose the right PCB

As a professional Lighting product

supplier, Seming Lighting knows the importance of PCB for ring lights. We have

a professional R & D team and advanced production equipment, can provide

you with high quality single-sided and double-sided PCB products, and provide

you with the following services:

Personalized consultation: Our professional team will provide you with personalized selection

advice according to your specific needs to help you choose the most suitable

PCB type.

High quality products: We provide high quality ring lamp PCB board, using high quality

materials and advanced manufacturing process, to ensure stable and reliable

product performance.

Customized services: According to your special needs, we can provide customized PCB

design and manufacturing services to meet your individual needs.

Sum up

The selection of the appropriate ring lamp

PCB board directly affects the performance, stability and service life of the

ring lamp. Single-sided PCB is suitable for applications with low performance

requirements and cost sensitivity, while double-sided PCB can provide better

electrical conductivity, heat dissipation performance and reliability, and is

suitable for products with high performance requirements.

Seming Lighting is committed to providing

customers with high quality lighting products and professional solutions. We

hope this article will help you better understand the difference between

single-sided and double-sided PCBS and make an informed choice based on your

actual needs. If you encounter any problems when choosing a ring light PCB

board, please feel free to contact Seming Lighting, we will be happy to serve

you. Let us choose the most suitable PCB for your ring light and light up your

life!